Operation

An Operation refers to any manufacturing operation performed on the raw materials to process it further in the manufacturing path.

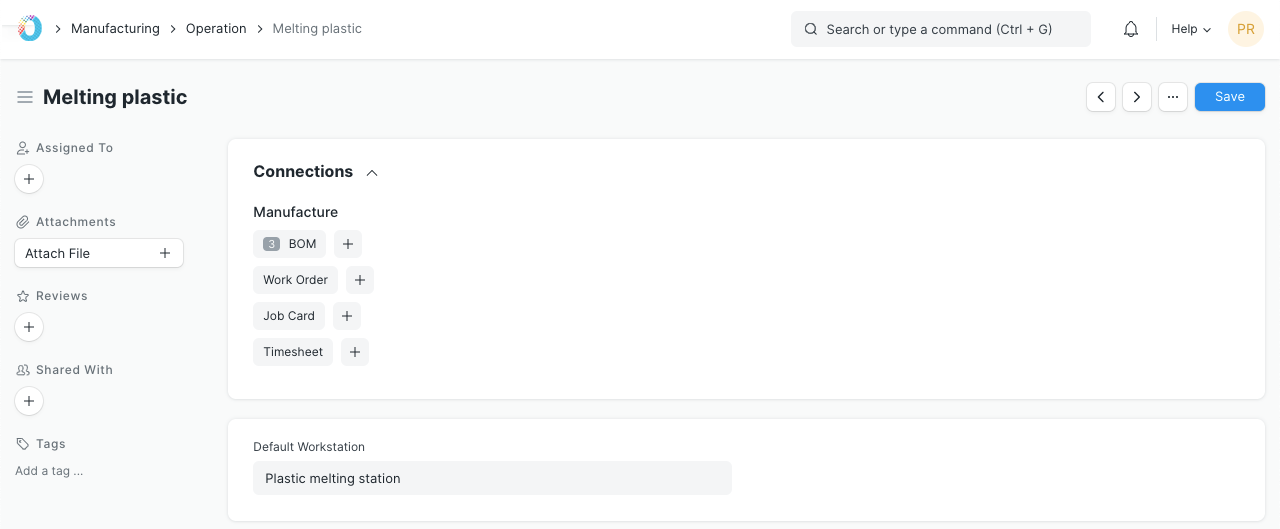

The Operation master stores a single manufacturing operation, its description and the Default Workstation for the Operation.

To access the Operation list, go to:

Home > Manufacturing > Bill of Materials > Operation

1. Prerequisites

Before creating and using an Operation, it is advised that you create the following first:

2. How to create an Operation

- Go to the Operation list, click on New.

- Enter a name for the Operation, for example, cutting.

- Select the Default Workstation where the Operation will be performed. This will be fetched in BOMs and Work Orders.

- Select a Quality Inspection Template for the operation in the Job Card section. It will be fetched on the Job Card for that particular operation when Work Order is created. When a new Quality Inspection is created from the Job card, then the same Quality Inspection Template is set for the Quality Inspection.

- Optionally, add a description to describe what the Operation involves.

- Save.

Once saved, the following can be created against an Operation: