Routing

Routing is a template of BOM Operations.

A Routing stores all Operations along with the description, hourly rate, operation time, batch size, etc. Creating a Routing for your BOM Operations is useful when similar Operations are used for manufacturing different items.

To access the Routing list, go to:

Home > Manufacturing > Bill of Materials > Routing

1. Prerequisites

2. How to Create a Routing

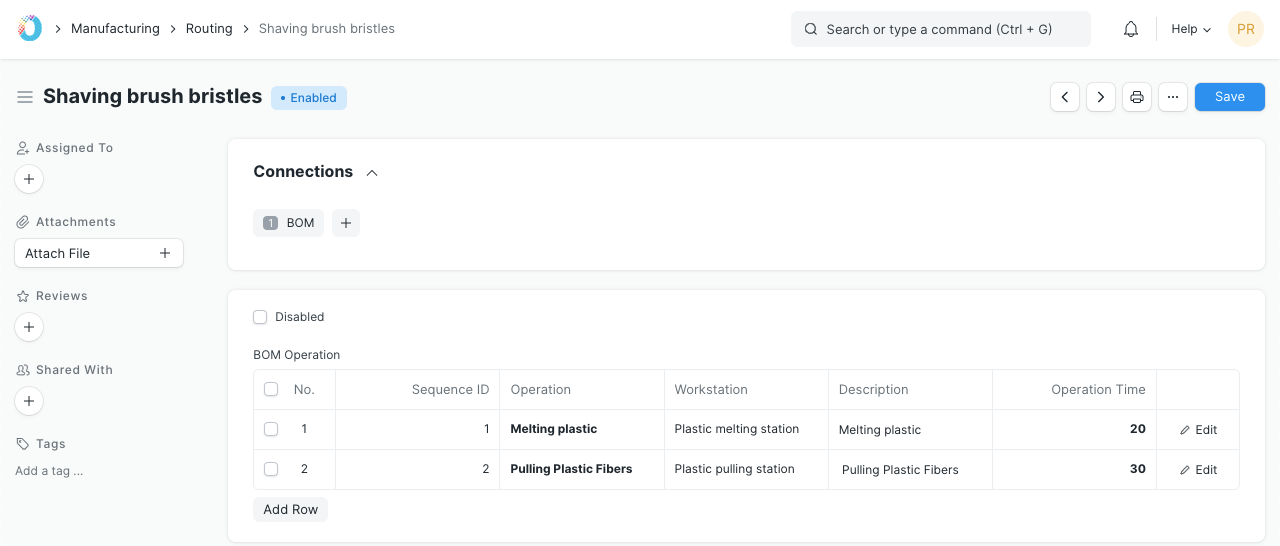

- Go to the Routing list, click on New.

- Enter a name for the Routing.

- Enter the Operations in the BOM Operation table:

- Select the Operation.

- The default Workstation will be fetched.

- Enter the Hourly Rate for running this Operation.

- Enter the Operation Time in minutes.

- Enter the Batch Size, i.e. the number of units processed in this Operation.

- The Operating Cost will be calculated based on the Hourly Rate and the Operation Time.

- Save.

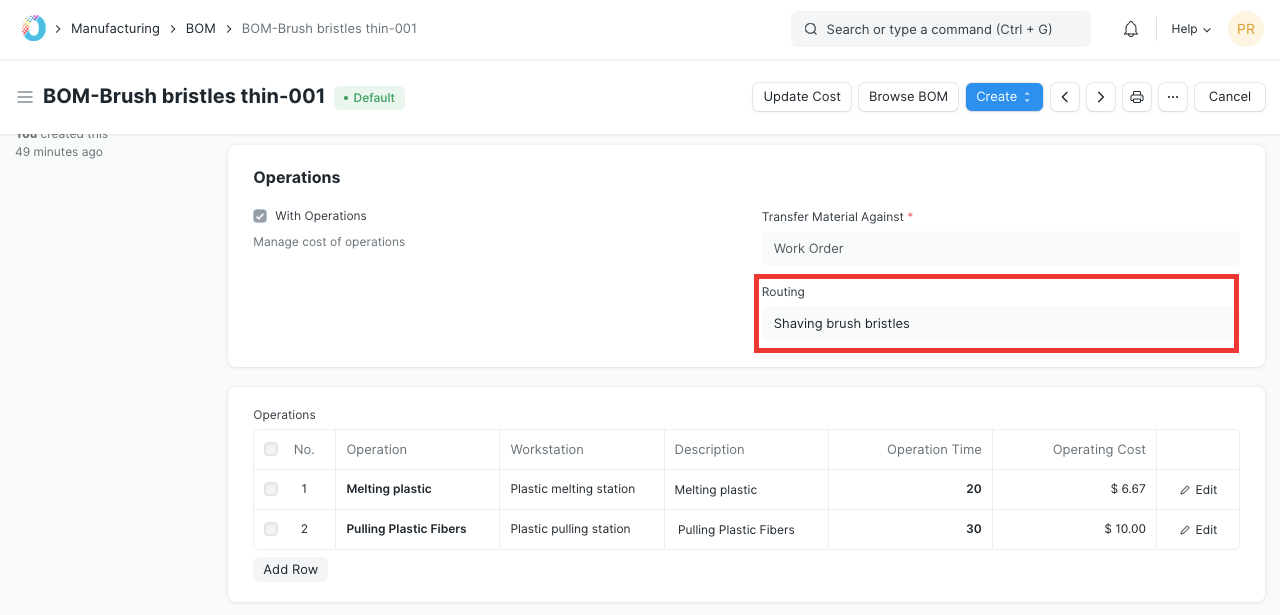

Once created, a Routing can be selected in a BOM to fetch the Operations stored in the Routing.

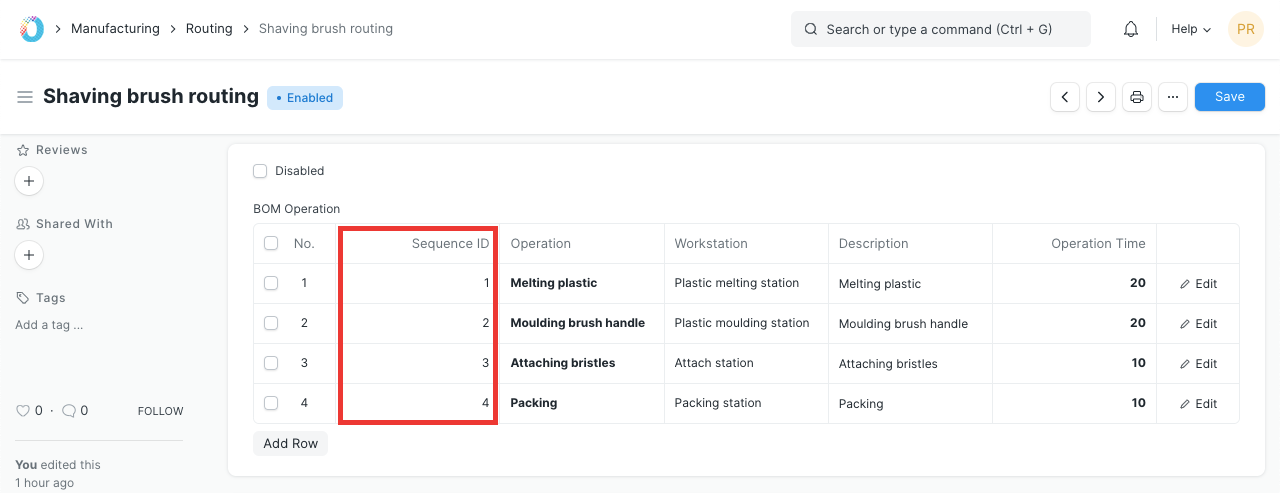

3. Sequence ID in Routing

Sequence ID enforces the users to complete the operations sequentially via Job Card. In case a user tries to complete an operation before completing any of its precedent operations as per the Sequence ID, the system throws a validation error.

Sequence ID enforces the users to complete the operations sequentially via Job Card. In case a user tries to complete an operation before completing any of its precedent operations as per the Sequence ID, the system throws a validation error.